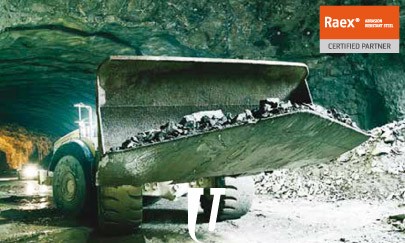

Mining steels

Mining steels also called anti-abrasive steels are special steels used in the mining sector (with anti-wear and anti-abrasive properties, AR for its acronym in English, Abrasion Resistant).

Brinell hardness tables for these steels range from 360/440 Hb to 450/540 Hb onwards.

Anti-abrasion

The wear of metals by abrasion occurs when the hard roughnesses of different elements: sand, rock, scrap, asphalt, cement, coke, coal, earth, wood, etc. they make contact on the metal scratching its surface and opening grooves upon friction, causing multiple cuts that rip the metal. This process is called indentation and causes deterioration and a reduction in the useful life of the metal.

Anti-abrasion treatments

Different heat treatments are applied to these steels to transform their microstructure and achieve improvements in their mechanical properties, among which hardness by definition is the main property. Mining steels (AR anti-abrasion steels) are usually low carbon steel alloys mixed with controlled proportions of various elements, among which stand out, Chromium (Cr), Manganese (Mn), Silicon (Si), Vanadium (V) and Nickel (Ni)