Materials for Special Steels

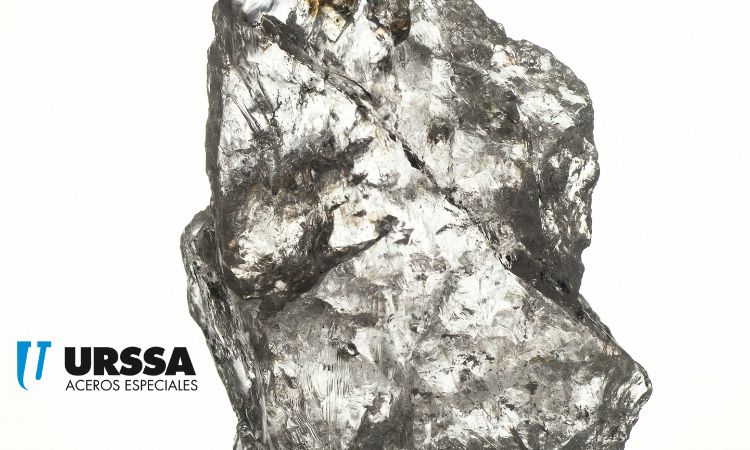

Special steels are a type of steels that possess unique and superior properties compared to conventional steels. These steels are used in a wide range of applications where superior mechanical strength, corrosion resistance, high thermal conductivity, specific magnetic properties, or a combination of these characteristics are required. Manufacturing of special steels involves the use of select materials and specialized processing techniques to ensure their outstanding quality and performance.

Materials used in special steels

Special steels are composed of a variety of alloying elements that give them their unique characteristics. Some of the materials used in the production of special steels include:

- Chromium (Cr): Chromium is added to steels to improve their resistance to corrosion and wear. Stainless steels, which contain high amounts of chromium, are widely used in applications where resistance to oxidation and corrosive media is required.

- Nickel (Ni): Nickel is used to improve the corrosion resistance, toughness and low temperature strength of special steels. Nickel steels are commonly used in the manufacture of equipment for the chemical and petrochemical industries, as well as in cryogenic applications.

- Molybdenum (Mo): Molybdenum is added to specialty steels to increase their high-temperature strength and improve their ability to withstand extreme mechanical loads. Molybdenum-containing steels are used in engine components, cutting tools, and high-temperature applications.

- Titanium (Ti): Titanium is used in specialty steels due to its high strength, low density and excellent corrosion resistance. Titanium steels are used in the aerospace, medical and oil and gas industries where a combination of strength and light weight is required.

Manufacturing of special steels

The manufacture of specialty steels involves a carefully controlled process to ensure the desired quality and properties. Alloy materials are melted in special furnaces and then subjected to a refining process to remove impurities. Controlled solidification of the steel into ingots or semi-finished shapes follows. These ingots are subjected to heat treatments, such as annealing, quenching, and tempering, to improve their strength and toughness. Finally, mechanical forming is performed to shape the specialty steel into final products, such as bars, plates, or wires, depending on the needs of the specific application.

Uses of special steels

Cutting tools: Specialty steels, such as tool steels, are used in the manufacture of drill bits, blades, milling cutters, dies and other cutting elements because of their hardness, wear resistance and edge retention ability.

Automotive industry: Special steels are used in the manufacture of automotive components, such as axles, gears, drive shafts and structural chassis parts, due to their strength and toughness.

Construction industry: In building structures, bridges and other infrastructure, special high-strength steels are used to ensure safety and load-bearing capacity.

Aerospace industry: In aircraft construction, special steels are used in critical parts such as engines, wings and landing gear due to their high fatigue strength and ability to withstand extreme conditions.

Oil industry: Special steels are used in the manufacture of pipes and equipment for oil and gas extraction, as they offer corrosion resistance, high toughness and the ability to withstand aggressive environments.

Medical industry: Specialty stainless steels are used in the manufacture of surgical instruments, implants and medical devices due to their corrosion resistance and sterilization capabilities.

Energy industry: Specialty steels are used in the manufacture of turbines, generators and other equipment for power plants, both conventional and renewable, due to their strength and ability to withstand high temperatures.

Food industry: Special stainless steels are used in the manufacture of food processing equipment and containers because they are resistant to corrosion and do not contaminate products.

These are just a few examples of the many uses of special steels in different industries. The versatility of these materials makes them indispensable in many technological and manufacturing sectors.