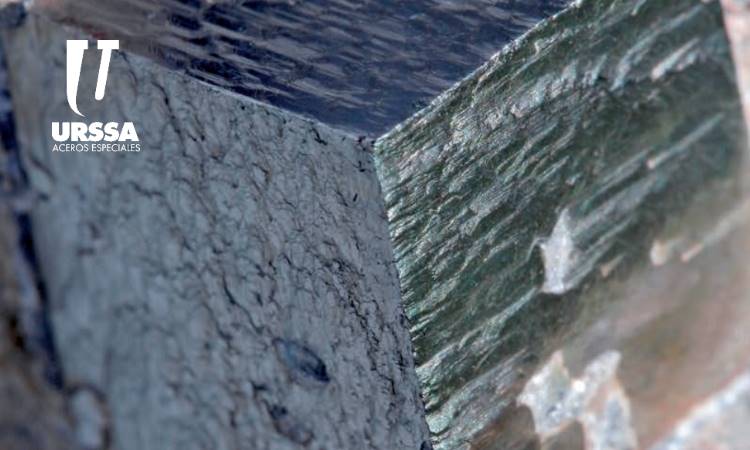

Abrasion steel

Abrasion in steel is a physical phenomenon that results from the gradual wear of the metal surface due to friction with solid abrasive particles or rough surfaces. This process can occur in a wide variety of industrial and everyday situations, from handling bulk materials to moving heavy machinery over metal surfaces. Abrasion occurs when abrasive […]

Boron steels

The alloys of boron steels allow them a superior resistance after hardening by heat treatment. Boron is generally added to medium carbon alloy steels to improve their performance and that these reach a similar performance compared to those of high carbon content, and other alloy steels, which involve a higher cost. It is preferred to […]

Special steels

A common way to classify steels is to refer to the current European standard EN10020, which classifies steels according to 7 main quality classes: Alloy steels Quality unalloyed steels Special unalloyed steels Stainless steels Other alloy steels Quality alloy steels Special alloy steels Steels with alloys whose objective is to achieve peculiar mechanical properties for […]

Refractory steels

Refractory steels are steels with low carbon and silicon content and high alloys: chromium (Cr) and nickel (Ni). These steels have a very good behavior against corrosion (ideal for oxidizing environments) and also high resistance to high temperatures (up to 1000Cº). They are excellent for welding processes and furnace coatings. Industrial uses: industrial furnaces, cement, […]